|

|

|

MANAGEMENT OF MERCURY CONTAMINATION AND ITS

MONITORING AT |

|

|

|

|

|

CONTENT |

About twenty years ago

such notions as “Environmental monitoring”, “Risk assessment”, “Contamination management” and “Risk management” were almost unusual not only in Russian but in

English as well. It was due to the recently developed scientific, technical,

economic and political related

spheres of human activity which rapidly grew during the last 20 years. Mercury was recognized as one of the

most dangerous pollutants only recently by

international medical and environmental institutions. Earlier mercury was

widely used in industry, agriculture, scientific researches and in household

activity. Recognition of “mercury hazard” appeared

due to the several

anthropogenic environmental catastrophes in XX century. The most famous one is

the mercury contamination of

The project of Demercurization of chlor-alkali

production in

Authors of this paper

took part in:

- the

field study in the Northern industrial zone of Pavlodar in 1993-1994,

- project

INTAS Kz 95-19,

- discussions

of BRGM (France) company proposals in 1999-2001,

- expeditions in the framework of «Toxicmanagement» project in

2001-2002,

- public

hearing of “Toxicmanagement” outcomes in

- development of Terms of Reference

for the correction of Demercurization Design worked out by JV “Evrohim”,

Kiev (JV Evrohim) in 1995.

- development of the Program for post-containment

monitoring in the Northern industrial area of

- field studies for obtaining incoming data on

demercurization works efficiency in 2004,

- including within the framework of the project

NMP2-CT-2004-505561 "BIOMERCURY",

- calculation of mercury amount released into

environment in the course of production process in the period of 1975-1994 (1310 tons),

- collection

of historical data and documents concerning chlor-alkali production at Pavlodar

Chemical Plant (PCP) and Demercurization program in

- preparation and discussion of the

Project Proposal with the experts of International Science and Technology

Center (ISTC) in Pavlodar - in June 2004 and in Moscow – in September 2004,

which currently approved for funding by US EPA as ISTC K-1240p project,

- preparation

of press-releases dated 15.11.2004 and 12.07.2006 on accomplishment of cut-off

wall construction (press

– releases were based

on this paper);

- post-demercurization

monitoring works since 2005 to date including work in the framework of K-1240p

ISTC project

1.

History of mercury electrolyses based chlor-alkali

production at the

The design statement for

the construction of the Pavlodar Chemical Complex (later it was renamed as PCP,

PO “Khimprom” Pavlodar, JSC “Khimprom”, JSC “PCP”, JSC “Kaustic”) was worked

out in 1962 being based on the following documents: Decree of National Economy

Supreme Committee of Council of Ministers of USSR #286-p /1/ dated November 29,

1963; Decrees of Central Committee of the Communist Party of Soviet Union and

Council of Ministers of USSR #795 dated July

23, 1958; #85-30 dated

January 20, 1960; #846-300 dated September 11, 1961 and also Decree of Council of Ministers of USSR #284 dated April 1, 1961. According to the

design statement the projected capacity was planed as much as 120 thousand tons

of caustic soda /2/, 90 thousand tons of liquid chlorine /1/. The construction of PCP started in 1965 and proceeded till 1992. For these years PCP has been managed by

several directors who ran the production. They are: Ju.B.Yezhov (1965-1968)

A.R.Bakhaev (1968-1973), A.C.Korpiakov (1973-1977), C.C.Berketov (1977-1988),

B.A.Sharov (1988-1997), E.P. Sereniuk (1997-1998), A.G.Siryk (1998-2000).

The first production –

mechanical-repair department was commissioned in

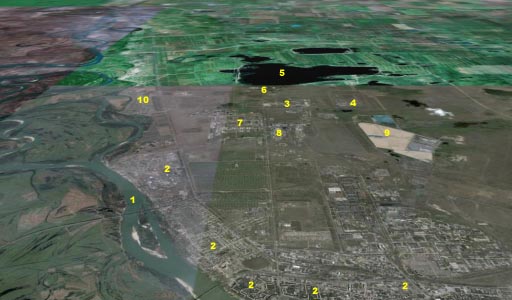

Location of PCP

which is

Fig.1. Northern industrial area of

At that time of planned

soviet economy further development of PCP was restricted by a number of

unfavorable factors such as delay in construction of oil-pipe line

Omsk-Pavlodar-Chimkent-Tchardzhou and POR. The latter was caused by the

construction in neighboring Russian oblast bigger Omsk Oil-Refinery. Other factors were: low quality of the halite material – brine from

Industrial Site #1

consisted of 30 shops where wide range of products and commodities was

manufactured such as caustic soda, chlorine, sodium hypo chloride, ammonium chloride, additives to lubricating oil and

engine oils, floto-reagents, anti-freezes, anti-icer, disinfectants and

bleaching agents, plasticizers for plastic mass production, phenol-formaldehyde

resin, some types of

plastic and plastic goods. These products were delivered to industrial plants

of the whole Soviet Union, including

In 1993 after the

termination of caustic and chlorine production which was the basic production

of PCP only those shops survived that produced household chemical goods and commodity (for example shampoo based on a ginseng

extract) and reagents for ore mining and processing and energy industries. Part of these productions was privatized in 1994 during establishment

of JSC “Khimprom” at that they used their facilities on the condition of rent. 90% of JSC “Khimprom”shares belonged to the state. The most standing idle equipment subject to any value were sold in

order to pay to minimum working staff and to cover the debts. The exception was

the defence equipment which were protected by

Soviet-American non-proliferation treaty dated 1989, ratified later also by the Kazakhstan Government. However

Demercurization works at

the cost of republican budget were resumed by JSC “PCP” only in early 2002. By 2005 the first Phase of

demercurization project was accomplished. In 2006 JSC “PCP” was proclaimed a bankrupt and its

property was put for a bid while the territory where demericurization works

were held was withdrawn from the bid lot and still is a communal property. New

chlor-alkali production (with membrane method) will be revived by JSC “Kaustic”

with private capital. JSC “Kaustik” was established in 2004 based on only

private capital and had purchased the half of the property of PCP industrial

site #1 by the beginning of 2006.

1.2.

Chlor-alkali production. History

/4-8/

Production #3 manufactured chlorine and caustic soda (NaOH) since 1975 till 1993 by

electrolysis method where mercury was used as a cathode. There were 80 electrolyzers (CDM 150-7.3) installed in shop #31 (in 1975 - 72 electrolyzers, in 1984 - additionally 8 electrolyzers, and after full repair in

1986 there were 68 electrolyzers totally). The capacity of production amounted

112700 ton of caustic

soda and 100000 ton of chlorine per year. Raw

materials sources: sodium chloride - from Baskunchak (

Horizontal electrolyzer CDM 150-7.3 made in Germany (with maximal load of 150 kA, cathode

current density of 7.3 kA/m2, length of

2NaCl + 2H2O →

2NaOH + Cl2↑ + H2↑,

was divided into two electrochemical

processes:

in the electrolyzer gaseous chlorine was generated on

graphite anode and sodium amalgam - on mercury cathode

2Na+ + 2Cl-

+ (Hg) → 2Na (Hg) + Cl2↑,

and in the decomposer both aqueous solution of

sodium hydroxide and gaseous hydrogen were generated on the surface of a

graphit extension as a result of interaction of sodium amalgam with water

2Na (Hg) + 2H2O →

(Hg) + 2NaOH + H2↑.

Technologically the

process of sodium hydroxide production looked like a travel of depleted sodium amalgam (with sodium concentration ≤ 0.005%)

from the lower part of

the decomposer upward to the electrolyzer inlet with the help of mercury pump, followed by the saturation of amalgam with sodium

under the current up to concentration 0.45 % during its move along sloping bottom of the electrolyzer, entering 0.45% of sodium amalgam from the electrolyzer in the upper part of decomposer and

the formation of NaOH

in the process of interaction of sodium with desalted water on the graphite

extension at trickling of amalgam down along decomposer with lowering concentration

from 0.45 to 0.005%. NaCl brine flowed forward with amalgam in the electrolyzer

while NaOH solution contra flowed to amalgam in decomposer. Concentration

of NaCl in brine at the electrolyzer inlet was 300-310 g/l, in anolyte

outlet - 265-275 g/l (anolyte contained dissolved 0.3-0.5 g/l chlorine). Alkali

solution concentration at the electrolyzer outlet was 43-46%.

Electrolysis brine was

prepared with anolyte additional saturation in the Shop # 34a where it was stored in two horizontal rubberized tanks of

Solutions temperature in

the electrolyzer reached 80-85оС, and in decomposer – 80-100оС. High temperature caused contamination with mercury of all

electrolysis products and wastes: anolyte NaCl depleted solution, solution of

alkali and hydrogen. Alkali was contaminated with elementary atomic-dispersed

mercury; anolyte, chlorine and exhaust gases contained water dissolved mercuric

chloride; hydrogen and output ventilation gases – gaseous mercury. In the long

period of electrolyzers operation a lot of mercury was sludged with the

formation of amalgam oil which was hand-removed regularly from electrolyzer’s

accumulating pockets. For amalgam cleaning the accumulating pockets were rinsed

with purified water.

Alkali solution was

cooled, separated from mercury and other admixtures by

filtering through frame filters FP-50 and afterwards alkali was passed for either

storage or being poured into tanks. Hydrogen was cooled to 20-25оС immediately above the

decomposer so that the most condensable mercury returned in decomposer.

Afterwards hydrogen was cooled again to 15-20оС with the return of condensed

mercury in electrolyzers, and mercury removal with chlorinated water took

place. Remaining chlorine was absorbed from hydrogen with alkali solution (with

NaOH concentration of 180-240 g/l), then purified hydrogen was rinsed with

water, diluted with nitrogen and emitted into the air. Mercury content in

emitted gases shouldn’t had exceeded 0.01 mg/m3.

In winter period however hydrogen was emitted into air skipping purification

stage. Received

in electrolyzers chlorine-gas with concentration Cl2 ≥ 90% and admixture of H2 gas ≤ 1%

was constantly pumped out in collector so that to maintain vacuum of 5-

Mercury that had been

lost during the electrolyzers operation as a result of leakage and during

repair was washed out with water from the electrolysis shop’s floor into the

floor troughs and further into settling pits of mercury contaminated wastewater

sewerage. Troughs and settling pits were periodically cleaned off using

portable titanium vacuum tank one of connecting pipes of which was connected to

vacuum line and another was connected to rubber hose with the help of which

mercury was collected. Collected mercury returned to the electrolyzers. The

floor of electrolysis shop was covered with special coating which was replaced

several times for all time of its operation.

The plant of mercury

sludge thermal regeneration was launched in 1980 with capacity of 150 m3/year and reached the capacity as much

as 48 m3/year. The plant consisted of 3 induction furnaces of

periodic activity. Each furnace had four cylinder baskets with welded

bottom. Heavily contaminated sludge (4-15%) was mixed manually with

sawdust and limestone in the ratio of 20:1:1 and loaded manually in the

baskets. The baskets were placed in the furnaces with the vacuum rate of 0.2 kgc/cm2. Heating was proceeded by

stages for 14-15 hours till the maximal temperature 550-600оС. For mercury vapor condensation a

vertical heat-exchanger with water casing and heat exchange area of

Wastewater sulfide

treatment was located in the buildings 40, 40a und 40b. This treatment plant

was launched in 1975 simultaneously with chlor-alkali production. Treatment

process consisted of pH correction of mercury bearing wastewater, settling of

primary mercury sludge, mercury oxidizing up to Hg (II) by chlorine followed by

removal of chlorine excess, second correction of pH and Hg (II) precipitation

from solution with the help of sodium sulfide. Poorly soluble mercury sulfide

(II) was settled with iron sulfate as a coagulant with following continuous

settling of mercury sludge. Treated effluents were collected in the tank 40d of

Fig.2. Storage tank

for mercury containing wastewater “40d”

There were some major

technological drawbacks of sulfide method: low rate of mercury sulfide sediment

formation, by-processes of soluble poly-sulfides formation and hardships of

solid phase separation. Therefore mercury concentration in wastewater

discharged from 40d tank in the wastewater storage pond did not meet the

standards very often. Besides Production # 3 discharged illegally wastewater to

the pond Balkyldak avoiding sulfide clean-up very often. It forced the

management of PCP to reconstruct the system of wastewater collection and

treatment. In 1978 sulfide based treatment plant was replaced with the facility

based on the ion-exchange however it was operated not regularly. Achieved capacity

reached 30 m3/hour. Wastewater were

filtered, acidified to pH 1-3 and chlorinated in a chlorinator at active

chlorine concentration of 0.1 – 0.8 g/l in the water for clarified water and up

to 2 g/l concentration for non clarified water. Then chlorinated water was

filtered again, de-chlorinated through adsorber filled with ARV charcoal of

Evaporation ponds –

special engineering testing ponds - were constructed in 1976. Their design

capacity was 200 m3/day or 73000 m3/year

of mercury containing effluents. Evaporation ponds are located

After the completion of

special evaporation ponds construction and mercury sewage systems

re-construction unapproved discharge of mercury contaminated wastewater from

chlor-alkali production into the general PCP’s sewage systems going to the pond

Balkyldak became technologically impossible. Communication between Production

#3 and the whole plant was disconnected. The anion–exchange treatment plant was

connected with the evaporation ponds via above-ground sewage system for mercury

contaminated wastewater – pipes made of titanium.

Wastewater storage pond

-

Approved load of metal

mercury for one electrolyzer was

Fig.3. South shore of

wastewater storage pond Balkyldak

Table

1. Production of

caustic soda and actual volume of mercury used at PCP /11/

|

Year |

Production of 100% NaOH, t/year |

Specific mercury

consumption, kg/t NaOH |

Mercury consumption

per year, t |

|

1975 |

17775 |

1.29 |

22.930 |

|

1976 |

9575 |

2.09 |

20.011 |

|

1977 |

28285 |

5.05 |

142.839 |

|

1978 |

36600 |

1.4 |

51.240 |

|

1979 |

43082 |

2.6 |

112.013 |

|

1980 |

42363 |

1.86 |

78.795 |

|

1981 |

59338 |

1.504 |

89.334 |

|

1982 |

48935 |

1.296 |

63.420 |

|

1983 |

55510 |

1.485 |

82.432 |

|

1984 |

66600 |

1.3 |

86.580 |

|

1985 |

57464 |

1.743 |

100.160 |

|

1986 |

38234 |

2.6 |

99.408 |

|

1987 |

57954 |

0.838 |

48.565 |

|

1988 |

61060 |

0.74 |

45.184 |

|

1989 |

62750 |

0.74 |

46.435 |

|

Totally, t |

685525 |

Average 1.589 |

1089.356 |

Actual specific mercury

consumption was as much as 1.589 kg/t, while “scientifically justified norms”

required the consumption of 0.3 kg/t, "technically justified norms" –

0.5 kg/t, and “designed norms” – 0.76 kg/t.

The balance of major

mercury technical losses was following: 0.8% of the losses fell at sludge

accumulated and treated during production process; up to 1.9% - vent emissions,

up to 2.6% - sludge sent to mercury factory, up to 3.9% - atmospheric

emissions with hydrogen, up to 11.8% - wastewater and solid sludge transported

to the ponds for solid and liquid mercury wastes, up to 83.7% - unaccounted

losses. The latter were caused by spills and leakage of metallic mercury and

its not full collection during operation and repair of the electrolyzers.

According to the

messages of the former PCP managers /12-13/ it is evident that in 1990-1993

(last period of chlor-alkali production) about 200000 tons of caustic soda was

produced and more then 175 tons of mercury was utilized. Totally about 2.6% of

used mercury was sent for treatment as sludge /11/, i.e. 33 tons. Former the

plant managers also informed /12-13/, that after chlorine production stoppage

and the following building and equipment dismantling (Shop # 31) about 140 tons

of metallic mercury was either poured out of equipment, collected from floors

or thermally extracted from sludge and sent to a mercury factory. Thus the

total loss of mercury during the whole chlor-alkali production process can be

estimated as high as 1310 tons, 1100 tons of which were unaccounted

losses accumulated in the concrete floor and grounds under the Shop # 31 and

its proximity. Chemically aggressive medium there caused quick deterioration

of the equipment of the chlor-alkali production. Electrolyses shop had a higher

then common accident rate because at the period of chlorine overproduction and

filling of all existing tanks with this gas the electrolyzers were either

de-energized or transferred to a lower current load. This adversely affected

electrolyzers’ technical status.

In 1986 Production #3 of

PCP underwent a scheduled capital repair. In 1988 Program of conversion of

technology based on mercury method which was used at electrolysis plants into

membrane technology was accepted in the

Main infrastructure of

the Production #3 was supposed to be kept as it was. The construction of the

new shop distracted the funds from the current repair and reconstruction of

building # 31. Unsatisfactory technical condition of chlor-alkali production

resulted in the Resolution of the

Production #3 was

finally stopped after the USSR collapse by the resolution of Plant director B.

Sharov /13/ in August 1993 after it was found out that the building #3 roof

began destroying because of corrosion and some components of building

structures started falling down into the hall of the electrolysis plant. In

January 1994 Ministry Cabinet of the

The following years PCP

management and local authorities were attempting to revive chlor-alkali

production in

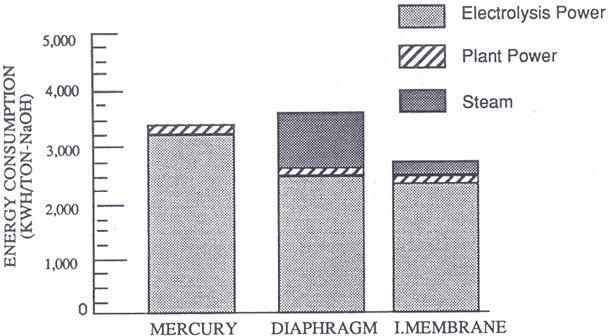

Table 2 and fig. 4 give

data /14/ proving economic advantages of membrane technology versus mercury and

diaphragm based one. However the main advantage of membrane technology versus

mercury one is the significantly low risk of environmental pollution.

In

Table 2. Comparison of Electricity Consumption for Each Technology

/14/

|

|

MERCURY

|

DIAPHRAGM |

MEMBRANE |

Current Consumption

(DC kWh/ton NaOH)

|

3000 - 3500 |

2300 - 2400 |

2200 - 2300 |

NaCl contents in

Product NaOH (50wt.%)

|

low(30 ppm) |

high(0.5-1%) |

low(20 - 50 ppm) |

Oxygen contents in Clorine |

low(0.1- 0.3%) |

high(2 - 3%) |

low(0.5 - 1.5%) |

Fig.4. Consumption of

Total Energy of each technology at chlor-alkali production /14/

1.3. Military history

of the plant and its conversion /3/

The Program of chemical

weapons development and stockpiling in the

PCP was one of such

plants which in peace time produced both civilian products and dual-purpose

products (caustic soda, Cl2, AlCl3, PCl3

etc.,) which could be used both for chemical and other kinds of weapon. PCP was

the last of big chemical plants to be constructed and in case of emergency it

can be converted easily into only military production manufacturing mostly

binary nerve agents which were developed in the

Although PCP

manufactured precursor chemicals for chemical weapon agents, it has never

produced chemical weapon. Since the early 1980s the construction of Site #2

went very quickly where since 1990 production of phosphorus trichloride –

initial material for organic synthesis of nerve agents was started. Many

specialists experienced in chemical weapon production were sent to the plant

that time. However the construction of technological lines for weapon

manufacturing was not accomplished. In 1987 the

Site #2 was located at

separated paled area of

The production process

at Site #2 started with manufacturing phosphorus trichloride. Yellow phosphorus

produced in southern

Table

3. Converted

production facilities at PCP Site #2 /3/

|

Buildings and their functions in

the production cycle until 1987 |

Buildings’ status in conversion

period from 1987 to 1992 |

Status as of June 1999 |

|

PCl3 production |

Civilian-use PCl3 production |

Civilian-use PCl3 production |

|

Production of intermediate

products for chemical weapon |

Production of civilian-use

substances: folitol, gidrel and acrylates in silver-lined reactors |

Production of civilian-use mineral

inhibitors in Hast-alloy reactors |

|

Chemical agent production |

Not completed |

Not in use |

|

Laboratory buildings |

Not completed |

Sold to a tannery |

|

War-shells filling |

Used for production of

polyvinylchloride (PVC) pipes |

Sold to Kazenergokabel, a wire

production company |

|

Laboratory for work with super

toxic substances |

Completely destroyed in 1987 |

|

|

Service facility |

Motor oil production |

Sold to Lyubol, Kazakhstani-Swiss

joint venture |

|

Incinerator for the elimination of

chemical wastes |

In use |

In use |

2. Program of

demercurization of chlor-alkali production at

2.1. Experience of

demercurization of chemical industries in the

In 1981 the chlor-alkali

production at JV “Khimprom”,

There was no any special

demercurization activity there. Mercury was poured out electrolyzers and other

equipment and utilized in new production. Demercurization of the equipment was

conducted by mechanical treatment of metal constructions and their rinsing with

water followed by their sending to metallurgical works for remelting. Concrete

building structures of the electrolysis factory were dismantled for a year and

used by population in private construction. Sludge and debris rich in

mercury was sent to Nikitovskiy Mercury Combine in

In 1987-88 the old

chlor-alkali production was closed down at PO “Kaustik”,

Dismantling of equipment

of the old chlor-alkali production took place under the pressure of local mass

media and NGOs requiring precaution measures to be taken because

2.2. Researches taken by JV “Evrohim”,

Engineering survey was

carried out in compliance with the following documents: “Measures on solution

findings of environmental rehabilitation of the territories contaminated with

mercury to be taken during the shutdown of mercury electrolysis based

production and its replacement with membrane technology in Pavlodar PO

“Khimprom” approved by USSR Ministry of Chemical Industry dated 31.12.88 and

the Decree № 89-35 of USSR Chief sanitary doctor “On ban of chlor-alkali

production at Pavlodar PO “Khimprom” dated 12.07.89.

Pavlodar Hydrogeological

Expedition – Science and Technology Centre “Technolog” (PHH) being a

sub-contractor of JV Evrohim carried out the following fieldwork in 1989-1990:

32 test and observation boreholes on 8 profiles and also 19 additional

boreholes located beyond these profiles were investigated around the shops #

31. Such amount of boreholes allowed hydro-geological conditions to be

determined which chlor-alkali production left behind after its shutdown as well

as rate of contamination in the west part of industrial site #1, including the

main source of contamination – hall of mercury electrolysis. A half of these

boreholes was drilled through the first aquifers and perched groundwater to the

depth of

102 soil samples were

taken from the depth of 0.25-

Mercury concentration in

water and soil samples was determined with atomic-absorption method in the

laboratories of “Ecohydrokhimgeo” (Almaty) and JV Evrohim.

The main results of

balance and hydrological study of chlor-alkali production of PCP were:

- estimated mass of

mercury lost since 1975 till 1989 during the operation of chlor-alkali

production is 1089 tons including 14 - 63 tons with hydrogen and vent exhausts,

- deposited

in floor and grounds under the electrolysis factory – 813- 866 tons,

- dispersed

in the area adjacent to the Production #3, along the roads, place for storage

of wastes and contaminated equipment - 42-45 tons,

- main hot spot of mercury contamination is located within the territory of

electrolysis shop 31 and has an area of

- area

of mercury contaminated soils in the Site #1 is as much as

- plume of

groundwater mercury contamination spreads from Shop 31 west-northwest direction

up to

- in

two cells (#1, 2) of evaporation ponds there are mercury containing sludge from

anolyte clean up. Mercury there represents sparingly soluble mercury sulfide.

Mercury contents in this sludge ranges from 0.01 to 0.33%. Totally

evaporation ponds accumulated 140 tons of mercury salts;

-

in water of the cell for liquid wastes of the special evaporation

pond – from 1 to 2 tons of dissolved mercury;

- pond

Balkyldak received mercury with wastewater discharge. Average mercury

concentration in the surface water of the pond reaches 0.01 mg/l, that is 20

times higher then MPCw. Taking in account the total volume of

wastewater legally discharged to Balkyldak and mercury concentration in these

wastewater one can estimate the total amount of mercury in water and bottom

sediments. It is equal to 10-15 tons;

- hydrogeological

forecast of the further mercury underground spread from PCP showed the

following rate of mercury movement: in perched groundwater and the first

aquifer - 20-46.7 m/year, in the second aquifer - 12-28 m/year and in the third

one - 46-56 m/year.

2.3.

Demercurization Design of JV Evrohim /21-25/

The development of the

project was carried out in 1988 – 1995 and coincided with the

Priority program of demercurization

developed by JV Evrohim as a result of the study of 1988-1992 lay in the dismantling

of the most contaminated parts of the Shop 31 - electrolyses hall (80

electrolyzers, other mercury bearing equipment, walls, floor slabs, etc…),

washing the dismantled structures at the place and their sorting out. Metallic

equipment after their treatment with oxidants (sodium hypo chloride, hydrogen

peroxide, potassium permanganate, nitric acid, ferrous trichloride) and water

and had to be utilized as a scrap metal, building structures with less then 1%

of mercury – to be put in the specially constructed landfill (a pit of

Main process of mercury recovery was

expected to be carried out with the use of plants of thermal demercurization of

concrete and mechanical demercurization of ground. At that concrete and ground

after recovery of the most amount of mercury from them also had to be placed to

the new sections of the landfill and filled up with ground-concrete mixture.

Concrete debris from the floor of

the electrolysis hall of 20х30 cm size with mercury concentration of 0.3-0.5% had to be treated in

the vacuum chamber electrical furnace of periodic operation under 700-750оС temperature for 2 hours.

It was planned to cool the air

containing mercury vapor in an air condenser with additional water cooling.

Metallic mercury had to be periodically poured into hermetically sealed

containers while the cooled air to undergo additional treatment with adsorbent

HPR-3p (activated charcoal soaked with ferrous trichloride), and then to be

emitted in the air through

Grounds with mercury concentration

more then 1% had to be cleaned from mercury by preparing the pulp and its

screening at the scrubber equipped with a trommel. The pulp poor with mercury

which was obtained as a result of this operation was partly dehydrated and sent

for ground-concrete mixture preparation and filling up the landfill with help

of a pump.

Grounds with concentration less 0.3%

(close to Shop 31) and less 0.02% (close to Shops 31a and 37) had to be

excavated from the depth down to

Ground-concrete consisted of (per

The landfill for mercury wastes had

to consist of sections (not less then 3 ones) and to have capacity up to

Rate of mercury recovery: at

ignition – 95, at screening - 85%, maximal mercury concentration in the buried

concrete – less 3.5%.

In 1995-1998 PCP conducted

procedures discussion and approval of all the documents related to the

Demercurization works with all appropriate authorities including Ministry of

Environment and Bio-Recourses of the

In 1996 JV Evrohim’s design was

supplemented with Feasibility Study on dismantling and demercurization of the

Electrolysis Shop.

2.4.

Proposal of Japan Consulting Institute /14/

During his visit to

- elaboration

of recommendations for appropriate technology of caustic soda and chlorine

production;

- study

of the stopped production with respect to maximal use of existing facilities

and minimal investment of additional funds;

- caustic

soda, chlorine and hydrochloric acid market research to determine the adequate

capacity of the plant;

- development

of recommendations for more efficient project implementation;

- financial

and economic analyses of the project implementation and providing results of

the estimation.

The plan of

the production conversion was developed based on both replacement of

electrolysis thechnology of chlorine and caustic soda production by membrane

one and allocation of new membrane electrolysis units together with the most

part of old equipment in new building. The plan of works proposed by JV Evrohim

was accepted as a basic plan of demercurisation. It was expected that the

funding for demercurization activity would come from the soft loan provided by

the Japanese Government. For this deal PCP had to get the guarantees of

Government if the

2.5.

Participation of BRGM Company (France)

In 1999 the Minister of

Mineral Resources and Environmental Protection of the

In compliance with the

original proposals of BRGM remediation of the mercury contamination in

Next variant,

“Demercurization project in Pavlodar: Environmental Impact Assessment and

contamination hot spots elimination” was proposed by BRGM six months later /27/

and had three phases: Phase I – works on ensuring safety of concrete floor in

Shop 31 (with durability of 2 months and cost of $0.3 millions of French

Government soft loan); Phase II (consisted of two parallel components at the

expense of French Government soft loan): component A – assessment of the

pollution scale and health risk for population in Pavlodar (duration –18

months, estimate budget - $4 millions), component B – demercurization of

Nevertheless the

protocol stipulated denial of JV Evrohim design as in compliance with the loan

terms “…local expenses, services and equipment made not in

i – dismantle

chlor-alkali facility, wastes sorting and burial in the temporary storage,

ii – reduce mercury concentration in

grounds and soils to the maximum permissible level through their thermal

treatment,

iii – ensuring the full safety of

PCP administration as

well as the local authorities didn’t accept the proposal to abandon JV Evrohim

design completely. It was suggested that BRGM should develop Feasibility Study

(FS) of their proposal /30/ for its further consideration as an alternative

project to JV Evrohim’s one. BRGM developed the project FS “Demercurization and

elimination of mercury source of contamination in

FS suggested conducting:

-

Collection of

additional data on soil-ground characteristics at the Site #1 and on bottom

sediments in the special evaporation ponds and the pond Balkyldak;

-

assessment of water quality in the river

-

simulation of mercury migration with both

groundwater and surface water as well as with the air which should be done to

assess the risk posed to population;

-

technical and economic assessment of

efficiency of different technologies of cleaning from mercury;

-

technical solutions developments on the site

rehabilitation to be funded by World Bank;

-

temporary encapsulation of concrete floor of

Building 31;

-

thermal treatment of

-

construction of anti-filtration screen – cut-off

wall around Building 31.

FS also suggested

approximate distribution of the loan funds (8.2 million Euros) as follow:

- technology

and equipment purchase and personnel training - 50%,

- data

collection and analyses, risk assessment - 25%,

- demercurization,

rehabilitation works at industrial site and construction of cut-off wall - 25%

.

After the comparison of

JV Evrohim and BRGM proposals /31/ it was evident that BRGM technology does not

drastically differ from JV Evrohim proposal however the cost of BRGM project

was much higher then that of JV Evrohim. For example, the method of mercury

recovery according to BRGM 20 times more expensive than that of JV Evrohim. In

compliance with the BRGM proposal

Comparison of JV Evrohim

and BRGM designs gave reasons to

2.6.

Demercurization activity in 1998-1999

Due to environmental

emergency situation at PCP the head of oblast administration D. Akhmetov

immediately after approving JV Evrohim design by MNREP in 1995 asked for The

Republican authority to fund the demercurization activity. It was expected that

the funding in 1996 would be provided by the Environmental Fund and national

budget but the Ministry of Finance reject the funding due to the budget deficit

(Letter to the RK Government of 07.03.96 №18-2-3/1644) and suggested using

the debt capital from foreign investors and other stake-holders interested in

production of caustic soda by non mercury method. Committee on Emergency showed

no support to The head of

Decision to allocate

funds from the National budget (246 millions tenge in 1998, 373,4189 million

tenge in 1999, 262,8295 million tenge in 2000, total: 882,2464 million tenge)

/33/ was managed to receive only after the project of demercurization was

separated from the project of construction of new production (Protocol of

meeting at Deputy Prime-Minister № 20-11/9195 of 15.08.1997). A considerable

pressure to take the decision to open the funding for demercurization activity

was rendered by the Russian Federation Government: in

In 1998 five years later

after the production stoppage dismantling of Building 31 (Fig.5-6) and wastes

burial was started. These works were funded from local budget because the

national budget could provide 9.3 million tenge for the first year /33/.

Dismantling of electrolyses shop was scheduled for winter 1998-1999 because

mechanical collection of mercury is safer under the cold temperature (mercury

vapor concentration inside the Building

Table 4. Cost of

demercurization works at chlor-alkali production in Pavlodar

Funding sources |

1996 |

1997 |

1998 |

1999 |

2000 |

2001 |

Total |

National budget |

- |

2.0 |

9.3 |

80.0 |

30.0 |

- |

121.3 |

Oblast budget |

0.4 |

0.6 |

26.5 |

10.7 |

13.3 |

16.5 |

68.0 |

Own PCP funds |

17.3 |

5.0 |

4.4 |

6.9 |

- |

- |

33.6 |

Total in the year: |

17.7 |

7.6 |

40.2 |

97.6 |

43.3 |

16.5 |

222.9 |

3. Assessment of

mercury contamination extend in

Mercury contamination

study held regularly since early 80s were initiated by the public being worried

with the high probability of contamination hotspot occurrence which was out of

control, as local authority had no power to control defense industry. This

concern was backed up with significant chlorine emissions from the plant

reaching the residential area.

All those researches had

limited funding and as a rule didn’t covered territories adjacent to the plant

due to the secret regime at the plant. Those researches showed the extent of

mercury contamination of soils in 90s didn’t go beyond limits of the plant

territory whilst surface water contamination was limited with the wastewater

storage pond Balkyldak.

Fig.5. Building 31 –

electrolysis shop (northern side) before demolishing the building, winter

1998/99.

Fig.6. Building 31 –

electrolysis shop (southern side) before demolishing the building, winter

1998/99.

Fig.7. Building 31 –

electrolysis shop (northern side) after dismantling the roof, winter 1998/99.

Fig.8. Building 31 –

electrolysis shop (northern side) after dismantling the roof, winter 1998/99.

3.1. Researches

related to groundwater and surface water protection /44-46/

Ministry of Geology of

It was reported that

after 1985 shoreline in the pond Balkyldak was constantly higher than

Special evaporation

ponds of

It was recorded that the

extension of contaminated groundwater area with exceeding MPCw occurred

around the Lake Balkyldak In 1985 mercury was found only in the boreholes

located in 10-

3.2.

Research of potential contamination of

The closed salt

There were 16 boreholes

drilled along 3 cross sections which were perpendicular to groundwater flow

from the west. Groundwater sampling was carried out monthly during the year

1990-1991. Water samples were analyzed by cold-vapor atomic-adsorption

spectrophotometer with detection limit of 500 ng/l.

Both groundwater and surface water samples contained mercury below this

detection limit.

3.3.

Study of snow cover and soil mercury contamination /48-52/

The study was conducted

by the

In winter 1990-1991 snow

cover of residential area and south part of North industrial area was

investigated with regards to mercury contamination. Exceeding MPCw for

mercury in the snow melted water was found around the gardening

cooperative “Khimik”. Most likely it was found the south end of the mercury

anomaly located to the north from the investigated area. In 1991-1992 the area

of interest was extended up to the north border of the PCP industrial site, and

besides 45 samples of snow melted water additional 32 samples of soil were

taken down to the depth of 50cm. In the gardens of the north suburb 96 samples

of fruit and vegetables were taken. Exceeding MPCw for mercury was

found in snow melted water around PCP over the vast area (southward of Pavlodar

Tractor Plant, westward

Study of 1993 included

the sampling of 150 soil samples from 28 boreholes (down to the depth of

These field works showed

the annual mercury contamination of snow cover coming from atmospheric

precipitation did not lead to significant contamination of soils around PCP in

early 90s because most likely this way of the mercury contamination spread had

short term of existence.

Project INTAS–Kz 95-19

funded by EU was accomplished by the team of “GeoKEN” Ltd. which later became a

part of

No exceeding of MPCs

for any of heavy metals was found except some cases of mercury presence close

to the north boarder of Site #1, as well as close to special evaporation ponds

on the shore of the pond Balkyldak (fig.9). However several hotspots with

increased mercury concentration (100 times higher then local background

concentration) were found mainly in local depressed areas where snow melted

water accumulate in springs. There were also hotspots with increased mercury concentration

(not exceeding MPCs) in soils and bottom sediments of oxbows of the

Average level of surface

water contamination with mercury in the pond Balkyldak was estimated as 1 µg/l

(2 MPCw).

Fig.9. Area of field

works on INTAS-Kz 95-19 project (points on the map - soil sampling points)

4.

Risk assessment of mercury contamination in Northern industrial site of

4.1.

“Toxicmanagement” Project

In 2002 the research of Pavlodar City Northern industrial site mercury

contamination financed within the framework of INCO-2 Program of the European

Union was completed. The project involved two-year program of field and

chemical-analytical works and also the development of mathematical model of

mercury contamination distribution with groundwater at the area of PCP carried

out by the Consortium of Kazakhstani and foreign universities, research

institutes and companies.

The Kazakhstani partners within the project INCO-2 ICA2-CT-2000-10029

"Development of cost-effective methods of minimizing risk from heavy metal

pollution in industrial cities: a case study of mercury pollution in

Pavlodar" ("Toxicmanagement") were BG Chair of Environmental

Technology of Almaty Institute of Power Engineering and Telecommunication (AIPET),

Institute of Hydrogeology and Hydrophysics (IHH), KazGU and INS. The foreign

partners were the Department of Civil Engineering of Southampton University,

Great Britain (SU) – the coordinator of the project, Consulting Company

"GeoDelf",

The results of the research were reported at the meeting of Presidium of

the National Academy of Sciences of the

4.2. Collection and study of archival data

In 2001 IHH, KazGU and INS collected archival hydro-geological data for

The collected data were

studied and analyzed by IHH and on the basis of a part of the data a database

was created with the software FoxPro 3.0, and also the Geographic Information

System IHH (GIS IHH) was designed with use of MapInfo 5.0 software. While GIS

IHH creating hydro-geological maps were scanned and then digitized. At the same

time the layers were formed containing the information about the location of

mapped boreholes and also objects rendering essential influence on hydro-geological

conditions such as: the

The scales of soil and ground mercury contamination within the

Fig.10. Area of field

works on the project ICA2-CN-2000-10209 «Toxicmanagement» (points on the map –

groundwater sampling points, black – mercury concentration in water below 500

ng/l, red – above 500 ng/l)

SU, KazGU, AIPET, INS and IHH

carried out three joint expeditions: in summer and autumn of 2001, and also in

summer of 2002; at the same time representatives of GeoDelf, SSEU, Stepnogorsk

Laboratory of Biomonitoring (SLM),

In the research of soil mercury contamination Consortium was guided by

results of fieldwork in northern suburb of

In 2001 samplings were carried

out according to a regular grid with steps of grid of 13, 20, 26, 125 and

In 2001 and 2002 during summer

fieldwork in the territory of the Industrial Site #1 INS daily measured mercury content in the near-earth layer of

atmospheric air using atomic absorptive photometer AGP-01. These measurements

were done also with the purposes of safety for personnel and were the

justification for protective coveralls and gas

masks use.

AIPET and KazGU carried out

investigation of groundwater in Northern industrial site of

Pavlodar with the help of the existing network of

observation boreholes (in total 304 boreholes have been observed) and also 89

boreholes were drilled additionally including 36 ones with diameter of

In summer of 2001 all

existing observation boreholes (including unaccounted, abandoned and lost) and

also 30 operational boreholes in Pavlodarskoe village and nearby industrial

enterprises were investigated within the area exceeding 200 km2

around of the electrolysis shop of PCP (Building 31). Their coordinates were

determined by use of GPS, and also measurements of water levels, water

temperature, рН, red-ox potentials were done.

With the help of submersible electric pumps the boreholes were pumped through

according to specially developed technique excluding a sample contamination and

water samples were taken to determine chloride and total mercury content. In

autumn of 2001 KazGU drilled 13 boreholes with diameter of

In summer of 2002 PHH drilled 36 new observation boreholes with diameter of

In 2001 and 2002 KazGU and INS

took samples of surface water from the

In 2001 AIPET and KazGU took

samples of bottom sediment of the wastewater storage pond Balkyldak in its

southwest part, along an imaginary chord linking its extreme southern and northern

points together and also in its northeast part. The samples were selected being at a boat from the depth down to

In 2001 55 samples of fishes were caught by KazGU out of the pond

Balkyldak: a silver crucian, a tench, a Siberian dace, a river perch. In 2002

30 samples of fishes were caught out of the

In

Soil and ground samples were

analyzed for total mercury content in laboratories of AIPET, KazGU and INS in

Pavlodar and Almaty cities; water samples - for total mercury contents,

chlorides, sulfates and sulfides and milk samples – for total mercury content -

in laboratories of KazGU and INS in Pavlodar; silt, fish and bio-materials

samples for total mercury content - in laboratories of AIPET and KazGU in

Almaty. In total 2060 samples of soil, ground, sludge and silt were taken and

325 samples of water and milk, 95 samples of fish tissue and other biological

materials were taken and analyzed for total mercury content.

The results of field research

and laboratory analyses and also sampling point coordinates were compiled into

Summary tables serving as a database for GIS AIPET designing. GIS AIPET was

designed using the program MapInfo 5.0 and ArcMap 8.1 on the basis of

topographical maps and plans of different scales, which first were scanned and

then digitized similar to GIS IHH. Having

interpolated the data about soil mercury contamination with the help of a

module Spatial Analyst of Inverse Distance Weighted (IDW) method AIPET produced

models and maps of mercury distribution over three upper soil layers

(fig.11-16). Based on the models

there were calculated capacities of mercury contaminated ground with

contamination levels of <

2.1; 2.1-10; 10-100; 100-1000 and >1000 mg/kg and

also amount of mercury deposited in the soil of contaminated areas.

4.4.

Investigation of mercury contamination of soil in the

territory of PCP and around it (fig.11-16) has allowed revealing some

large centers of contamination with mercury concentration which was 500 times

more than MPCs for mercury (2.1 mg/kg): four of them were at the territory of

the Industrial Site #1 and came from the electrolysis shop 31, the shop of

production solutions regeneration, tanks for mercury containing wastewater

storage and the building of mercury contaminated wastewater treatment plant;

one of them was on the shore of the pond Balkyldak and was connected with

special ponds for storage of mercury wastes.

Three mercury hotspots at the

The hearth of soil mercury contamination in the area

of the special ponds was rather shallow and was formed by wind transfer of

dispersed solid mercury containing wastes.

Fig.11. Map of

topsoil (0-

Fig.12. Map of soil

(10-

Fig.13. Map of soil

(20-

The location of one of two (the western one) less

intensive hearths of topsoil contamination between the Industrial Site #1 and

the special ponds has overlapped a contour of spread of plume of mercury

contaminated groundwater and, probably, was caused by their reach of a surface

at the cost of evaporation and capillary effects. Second hearth (eastern),

probably, was formed by leaking mercury containing wastewater from the sewerage

system and their accumulation within this area. This assumption was proved by

numerous detection of high concentration of mercury in the borehole 7Р (4250

ng/l in 2002) made by different organizations within many years.

Amount of soil and ground in the layer of 0-

The level of mercury

contamination in atmosphere near to the Building

Investigation of existing observation and production

boreholes in 2001 showed that the spread of groundwater with mercury contents

more than MPCw (500 ng/l) was confined within the territory of the Industrial Site, places

where the sewerage system went and area of the special ponds. Numerous

investigation of the borehole 24-91, located

Fig.14. Map of

topsoil (0-

Fig.15. Map of soil

(10-

Fig.16. Map of soil

(20-

The drilling in

Fig.17. Hotspots of

groundwater contamination with mercury above 500 ng/l

according to 2002 investigation of observation boreholes

Surface water in the special ponds being accumulated

because of atmospheric precipitation was contaminated with mercury up to a

level of 50 mg/l (100000 MPCw), in pits to the south from the

special ponds - from 3 to 30 µg/l (6-60 MPCw), in the drain going

along the motorway in the direction to western dam of the pond Balkyldak - from

2 to 18 µg/l (4-36 MPCw), in the pond Balkyldak near the special

ponds - from 3.5 µg/l (7 MPCw) up to 100-300 ng/l (0.2-0.6 MPCw)

in shoaling water along the rest of the coast. The mercury contents in water of

an unfinished emergency canal extended from the pond Balkyldak to the Irtysh

River was not more than 10 ng/l (0.02 MPCw), in floodplain lakes of

the Irtysh River near the villages Pavlodarskoe and Shauke - not more than 9

ng/l (0.018 MPCw), in the Irtysh River - was lower than the

detection limit 2 ng/l (0.004 MPCw) of used analytical procedure.

The mercury concentration in the sludge of the special

ponds ranged from 10 mg/kg to 10000 mg/kg (2-2000 MPCs), in bottom sediment

of the pond Balkyldak – from 1 mg/kg to 500 mg/kg (0.5-250 MPCs). Groundwater

moving from the special ponds to the pond Balkyldak on the depth of 1.5-

Silver crucian is the main fish

species living in the pond Balkyldak. Predatory fishes were not found there.

Total mercury concentration in tissue of fishes caught from the pond Balkyldak

ranged from 0.18 up to 2.2 mg/kg and exceeded MPCf for non-predatory

fishes (0.3 mg/kg) in most cases. Concentration of mercury in tissue of

predatory fishes (mainly pike) caught in the

Gramma grass taken near the 6th wastewater pumping station contained

mercury from 1 mg/kg to 2 mg/kg, however, mercury contents in milk, kidneys and

liver of cows pastured in the territory between the Industrial Site #1 and the

pond Balkyldak did not exceed a similar parameter for these products from other

not polluted areas. Two samples of a hair belonged to employees of PCP

contained mercury at the same level as a hair of residents of Almaty.

4.5.

There is an aquifer in contemporary alluvial sediments

of the Irtysh River floodplain (аQIV), an aquifer in upper

quaternary sediments of the first above floodplain terrace (аQIII) and a water-bearing complex

in Falunian of low-middle-Pliocene sediments of Pavlodar suite (N1-2pv)

within the research area confined by the Irtysh River, the main irrigation

canal, the ash lagoon of power plants TES-2 and TES-3 and the Lake Muyaldy.

Clays of Kalkaman suite of Neogene are the first regional basalt layer.

The aquifer in contemporary alluvial sediments in

the western part of the research area looks as a narrow strip along the Irtysh

Riverbed. Water holding rocks consist of coarse sand with inclusions of grit

with capacity of 4-

Aquifer in upper quaternary alluvial sediments of the first

terrace above the floodplain occurs over the most part of the research area.

Water holding rocks consist of medium-size and coarse sand; small-grained and fine

sand and clay sand are less frequent there. There is

underground water there. The depth of occurrence of a daturence surface ranges

from 1.5-3 down to 6.5-

Aquifer in falunian of low-middle-Pliocene sediments of

Forming of groundwater of the area under natural conditions was mainly

occurred due to the infiltration of atmospheric precipitation and inflow on

external borders. The groundwater of contemporary sediments,

upper quaternary sediments and the one of

The wastewater discharge into the pond Balkyldak

began in

4.6. Main content of works on simulation

hydro-geological conditions

In 2001-2002 the work of IHH on creating the model involved following

basic stages: (i) schematization of natural conditions, (ii) preparation of

initial data, (iii) creation the model itself and its calibration, (iv) solving prognosis tasks.

At the first stage all collected information was looked through and

analyzed, their comprehensiveness, reliability and consistency were estimated.

The model of process has being chosen. The borders of the model were designed

and their schematization with boundary conditions and also the schematization

of simulated object (the quantity of layers was determined) was carried out,

the requirements to grid approximation of simulated area in horizontal

projection were determined. Created GIS IHH and database were used to analyze

the data. For the modeling process the system GMS 3.1 was acquired; it was

installed into a computer network of IHH, documentation on use of the system

was translated to Russian.

The initial data for modeling were prepared in accordance with the

results of schematization of hydro-geological conditions and peculiarities of

the modeling system GMS 3.1. Maps of hydro-geological parameters were produced

for each layer of the model. Values of dynamic parameters describing processes

on borders of the model (water levels in wastewater storage ponds Balkyldak and

Sarymsak) were calculated for every time step. The preparation of the initial

data was carried out using the GIS and the database.

The prepared initial data were converted to formats used by the modeling

system GMS 3.1. It was calibrated to prove the model is adequate to natural

conditions. In process of calibration the conditions existing for the

undisturbed period (1970) and then for the period since 1970 till July 2001

were reproduced in model. By fitting parameters they achieved coincidence of

solutions obtained in the model, with the facts obtained as a result of field

research during the last years and summer of 2001. When the coincidence

appeared to be satisfactory it was accepted that the model adequately described

hydro-geological conditions and could be used for forecasting their change. For

the production and calibration of the model the program

4.7.

There were solved both inverse stationary and inverse non-stationary

problem. The stationary problem which was being solved,

represented the year 1970. During solving the non-stationary problem the period

since 1970 till the middle of 2001 was reproduced in the model. An average

error of the solution of the inverse stationary problem was about

Fig.18. Spread (m) of

plume of groundwater contaminated with mercury up to 500 ng/l

(red area – on the results of field work of 2002, blue contour - on the result

of simulation of hydro-geological conditions as of 2002)

Three variants of the prognosis were made in the model:

- the first variant allowed for keeping two

sources of mercury contamination of groundwater (under the shop 31 and in area

of 6th wastewater pumping station), and also that hydro-geological condition

would remain at the same level as in 2001. The prognosis was done for case if

the concentration of mercury in the sources remained constant during all the

prognosis period;

- according to the second variant of the

prognosis the source under the shop 31 was completely isolated with help of

cut-off walls;

- according

to the third variant two sources of mercury (under the shop 31 and in area of

6th wastewater pumping station) remained the same, but however it was simulated

cessation of water delivery from the Irtysh River onto a water treatment plant,

located to the west from the Industrial Site #1 of PCP.

Based on the results of the simulation (the first variant of the

prognosis), it was established that the plume of groundwater polluted with

mercury would spread to the north-northwest direction at the depth from

4.8. Conclusions and recommendations of

“Toxicmanagement” project

Mercury contamination

of groundwater used for drinking water supply.

In northern and northwest suburbs of

Mercury

concentration in water and fish of the

Mercury contamination levels in the area of the

former electrolysis shop. It is necessary to finish the works projected by

JV Evrohim as soon as possible and connected to encapsulation of the main

hearth of the contamination from an environment. The building 31 should be

demolished and its building structures placed into a landfill. Also

construction of the bentonite cut-off wall reaching down to regional basalt

clay layer should be completed. If the cut-off wall functions in accordance

with the plan and prevents the groundwater containing soluble salts of mercury

from further horizontal spreading there is no necessity to take out and clean

the concrete floor slab of the electrolysis hall of the shop 31, and also

ground under it. The thermal treatment of the construction materials, strongly

contaminated with mercury can be postponed for the future, when mercury price

probably increase and its extraction becomes economically justified. However in

this case it will be necessary to isolate things confined by the cut-off wall,

so that it will become impenetrable for atmospheric precipitation from outside

and mercury vapor from inside that will stop polluting an atmosphere. It will

require construction of specially designed cap (which also should stop

capillary lifting) further to the works which were designed by JV Evrohim’s

design.

Fig.19. Spread (m) of

plume of groundwater mercury contamination on the results of simulation of

hydro-geological conditions as of 2031 (first prognosis scenario)

Fig.20. Spread (m) of

plume of groundwater mercury contamination on the results of simulation of

hydro-geological conditions as of 2031 (second prognosis scenario)

Fig.21. Spread (m) of

plume of groundwater mercury contamination on the results of simulation of

hydro-geological conditions as of 2031 (third prognosis scenario)

Mercury contamination of

soil around chlorine and caustic soda production. The soil

contaminated above sanitary norms which is outside the territory confined by

cut-off wall, should be taken out and placed into specially designed landfill

and isolated from action of groundwater and atmospheric water.

Mercury

pollution of ambient air. Under

demercurization work carrying out it is necessary to take dust-depressive

measures, to use more efficient temporary covering for mercury contaminated soil and the concrete floor slab of the hall of the shop 31,

and also to stop using the existing plant for thermal treatment of mercury

containing construction materials (fig.22).

Fig.22. Plant for

thermal demercurization of solid waste

Spread of the mercury

contaminated groundwater plum. The plum of mercury

contaminated groundwater does not threaten the

Special

evaporation ponds for liquid and solid mercury wastes.

In addition to work stipulated by JV Evrohim demercurization project it is

necessary to isolate the special ponds for mercury wastes with the help of

bentonite cut-off wall reaching the regional basalt clay, and specially

designed cap, impenetrable for mercury vapor and atmospheric water.

Wastewater storage pond

Balkyldak. FISH FROM WASTEWATER STORAGE POND BALKYLDAK CONTAINS

TOXIC LEVELS OF MERCURY. FISHING FROM THE POND SHOULD BE PROHIBITED IMMEDIATELY

AND THE ACTIVE STEPS FOR IMPOSING THIS BAN SHOULD BE UNDERTAKEN. It is

necessary to continue studying the wastewater storage pond Balkyldak status in

order to make long-term decision associated with its mercury contamination.

4.9.

Additional researches of IHH: simulation of hydrological processes in the

Northern industrial site of

On the base of the model

of 2002 developed during “Toxicmanagement” project implementation IHH made in

2003 the forth scenario of the plume spread in case of full confinement of two

sources of contamination with help of cut-off wall (under the Shop 31 and 6th wastewater pumping station).

This scenario (fig.23)

showed that without these two sources of contamination the plume in 2005 must

split into two areas. At that by 2031 the south area will decrease to

With the help of the

hydrological model of Northern industrial site of

Fig.23. Spread (m) of

plume of groundwater mercury contamination on the results of simulation of

hydro-geological conditions as of 2031 (fourth prognosis scenario)

5. Correction of JV

Evrohim design /58, 59/

Correction of the

working design of demercurization developed by JV Evrohim in 1995 was

recommended by National Academy of Science of the Republic of Kazakhstan (the

letter of Vise President of NAS RK #481 of 13.05.2003) /60-61/. Necessity of

such correction was caused by the fact that scope of work specified by the

project and accomplished in 1998-1999 prevented substantially the tread of the

It was also found that

the special ponds for liquid and solid mercury wastes were very dangerous

source of an environment contamination by mercury and need to be isolated from

groundwater and ambient air urgently but not after completing first stage of

demercurization works as it was scheduled in the project of 1995. At the same

time it was ascertained that for the period of time passed since 1993 the

buildings of the chlorine and caustic soda production had come to state of

nonoperability and become the source of environment pollution by mercury and

could not be used in productions newly being created. That brought to necessity

to dismantle the building structures and equipment of the shops with their

following demercurization.

Taking into account the

technical characteristics of demercurization objects, their location in the

industrial site and accumulated experience in demercurization activities the

next methods of demercurization were suggested by the correction of the working

design:

- confinement of both hotspots of groundwater mercury

contamination and special evaporation ponds for mercury wastes with help of

cut-off walls,

- excavation of topsoil heavily

contaminated with mercury down to the depth of

- construction

of a cap impermeable for mercury vapors and atmosphere precipitation on the top

of areas confined by the cut-off walls including special evaporation ponds,

- demercurization

of buildings and production structures through their dismantling, cleaning from

sludge and debris followed by burial of the mercury containing wastes in

the special ponds,

- creation

of network of observation boreholes and acquisition of equipment for mercury

monitoring to be done.

These technical

decisions were amendments to the scheme of the whole demercurization project.

They were chosen on the base of experience accumulated at PCP during the

demercurization and lay in following:

5.1. isolation of

hotspots of mercury contamination and the special evaporation ponds from

groundwater impact was carried out by constructing cut-off walls made of

bentonite clays which reached the basalt clay,

5.2. surface

screening on contamination sites was carried out with piling and compacting

bentonite types local clays on the top of the layer of clean soil,

5.3. burial

of demercurization wastes and debris was planned to do at the evaporation ponds

with following the ponds isolation,

5.4. isolation of filled

special evaporation ponds from atmosphere was carried out by creating

multi-layer cap: (i) intermediate leveling layer was consisted of materials

from dismantled dams’ crests, (ii) sorption layer was consisted of ash from the

power plant and served for prevention of capillary rise of water and substances

dissolved in it, (iii) waterproof layer was consisted of bentonite types clay,

(iv) and protection of the cap against rainfalls was provided by the layer of

fertile land with vegetation,

5.5. asphalt

top covering on the landfill for mercury wastes filled up with clay-concrete

mixture was designed for dusting prevention,

5.6. made decision on

demercurization and construction of caps and coverings allow using these areas

in future for constructions on their surface light buildings and structures

without foundations and underground communications network.

Fig.24. Construction

of anti-filtration screen, so called cut-off wall around the building 31

Fig.25. Bucket

(grifer) of hydraulic excavator “ЭО-522А”

Fig.26. Construction

of anti-filtration screen, so called cut-off wall around mercury waste lagoons

Fig.27. Creation of

clay covering above the concrete foundation of the building 31

Fig.28. Piling

mercury contaminated building structures into the first compartment of landfill

Fig.29. Piling

mercury contaminated building structures into the third compartment of landfill

Fig.30. Filling in

the first compartment of the landfill with ground-concrete mixture

Fig.31. Landfill for

mercury waste within the Industrial site #1

6.

Completion of first Phase of chlor-alkali production demercurization program of

2002 – 2004 /62/

In 2002-2004 Building

#31 was dismantled as well as Buildings 34, 34a, 34b (only concrete floors of

these shops were kept) and tanks of Shop # 34b and 6th pumping

station; Buildings 37, 36, 36b, 31d, 109 and water recycling communications

were decontaminated; infrastructure objects including overpasses and rail and

auto ways were either carried to different places or dismantled; cut-off wall

For three years the

works 860 millions tenge were spent, including 295 millions tenge - in 2002,

242 millions tenge – in 2003 and 323 millions tenge - in 2004. Totally since

May 1996 till December 2004 10867.97 thousands tenge were spent in reference

prices of 1991 (about $15 millions) which was 1082.56 millions tenge in

established prices. After the demercurization program completion the

implemented works were approved by State Expert Commission.

State Expert Commission

noticed that grounds for making all technical solutions was the results of the

special high quality studies and the most efficient integrated decisions were

chosen among various possible variants. It was also emphasized that such

decontamination project was the first to be implemented throughout the former

7. Program

of post-demercurization monitoring in Northern industrial area of

7.1.

Development of the Program of post-demercurization monitoring for 2005–2020

/57/

Program of

post-demercurization monitoring in the Northern industrial area of

The main goals of

Program of the mercury monitoring were (i) determination of levels of mercury

content in various environmental objects (atmosphere, soil, surface water and

groundwater) which remained after implementation of the Program of

demercurization of chlor-alkali production at PCP, (ii) control over

these levels changes during 15-year period, and (iii) confirmation of

acceptable level of risk posed from the residual mercury contamination for public

health, including population of northern suburb of Pavlodar and people working

on the territory of PCP.

Field studies and computer simulation carried out in the framework of the

“Toxicmanagement” project in 2001-2002 /55/ have shown that the major risks caused

by mercury contamination in area of PCP were connected with mercury

contamination of groundwater and surface water as well as with evaporation of

mercury on sites of the most intense contamination of soils.

As a result of implementation of the Program of demercurization the risk

caused by pollution of atmosphere by mercury should be completely eliminated.

Entering of mercury to natural water will also be stopped that in turn will

lead to their gradual self-cleaning and reduction of the

risk related to the mercury contamination of groundwater and surface water. One

should expect keeping some level of mercury contamination of soil in area of

PCP however the area of this contamination is not expected to spread further.

Therefore the monitoring of mercury contamination in the area of PCP should

include the following components:

- control over exceeding

of MPCgm for gaseous mercury equal to 300 ng/m3, in near-eath atmospheric layer (

-control over exceeding

of MPCs for total Hg, equal to 2.1 mg/kg

in the soil layer covering mercury landfills;

- control over absence

of spread of mercury pollution in soils with Hg exceeding MPCs for

total Hg equal to 2.1 mg/kg outside of original mercury aureoles (including at

the cost of evaporation of mercury contaminated groundwater) and control

over absence of accumulation of mercury inside of original hotspots of the

mercury contamination;

- control over absence

of spread of groundwater with Hg concentration exceeding MPCw for

dissolved inorganic mercury equal to 500 ng/l toward Pavlodarskoye village and

the Irtysh River;

- observation

over decrease in total Hg concentration in groundwater, including the

groundwater within the mercury pollution plume;

- control over absence

penetration of Hg dissolved into groundwater outside of cut-off wall and

landfills for solid mercury wastes; and observation over level of groundwater

inside of the isolated volumes;

- observation

over levels of total Hg concentration in surface water of the Northern industrial

area of

- observation

over levels of total Hg concentration in fish of wastewater storage pond

Balkyldak.

To achieve these

objectives the following tasks had to be solved:

- determine the

order, periodicity and methods of air, soil and water sampling for their

analysis for total mercury;

- determine the order

and periodicity of other field activities and measurements;

- determine the methods

of chemical analyses for total mercury in samples and order of laboratory

works;

- develop

recommendations on the obtained results interpretation;

- determine resources

needed for the mercury monitoring.

The results of suggested

Program of mercury monitoring should answer the question whether the

demercurization activities of 2001-2004 at the area of PCP were sufficient. In

case of decease in the residual mercury contamination to the level of

acceptable risk the Program of mercury monitoring can be completed in

7.2.

Field study in the Northern industrial area of

In September 2004 AIPET

and PCP undertook a joint field and chemical-analytical studies in the Northern

industrial area of

Comparison of the data

of 2004 (fig. 32) and one received on “Toxicmanagement” project in 2001-2002

showed that as a result of man-caused intervention in hydro-geological

conditions at the area of mercury hotspots in 2003-2004 some local changes in

mercury concentration in groundwater within the contamination plume have

happened.

In some cases when a

borehole happened to locate in the site surrounded by a cut-off wall

concentration of mercury could go up drastically, for example 100 times

increase in mercury concentration was found for the borehole P3. The same

happened for the boreholes located in the site of ruined sewage communications,

for example 10 times increase in mercury concentration was found for the

borehole 87-02, and double one - for borehole B21a. At the same time the

boreholes located in the immediate vicinity to cut-off wall showed decrease in

mercury concentration there, for example, double decrease in mercury

concentration was found for the boreholes 566-00 and 567-00. For the most boreholes

located quite far from the area of demercurization works the change in

concentration level in groundwater did not happen.

Study of new boreholes

drilled in 2003 proved the high level of mercury concentration in groundwater

within earlier found hotspots, especially near the special evaporation ponds.

Besides one more hotspot was found in the site of former mercury sewage system

connecting the industrial site #1 and the special evaporation ponds.

Levels of mercury

concentration in the surface water in the area of demercurization works

increased significantly, including ones in shoaling water along south-west

shore of the wastewater storage pond Balkyldak. It came from the relocation of

great volumes of dust-forming mercury contaminated soil.

Levels of mercury

concentration in soils in the area of demercurization works remained

considerably high, which probably was accounted for non-completed activity at

the moment of sampling. The same places where soils were heavily

contaminated by mercury were the main sources of mercury entering to

atmosphere. Levels of soil mercury contamination outside the mercury hotspots

(for example westward from Central Laboratory) remained

insignificant.

Fig.32 Results of

mercury monitoring campaign in Northern Industrial Area of

It turned out that

in September 2004 it was hard to estimate a long-term impact of the

demercurization works on environment in the area of PCP due to the incompleteness

of this works that time. One can notice local short-term increase in level of

mercury danger in the area of the works caused by dust forming and mercury